During our time designing fashion brand graphics and the physical product branding for the clothing itself, we have created all kinds of woven labels, swing tickets, cuff overriders, collars and pocket inserts.

These items usually feature the brand logo and are mostly for the purpose of displaying the garment size, care instructions and a barcode to allow the garment to be chosen and paid for. These are most often thrown away after purchase, whereas woven labels are the permanent display of the brand for the life of the product.

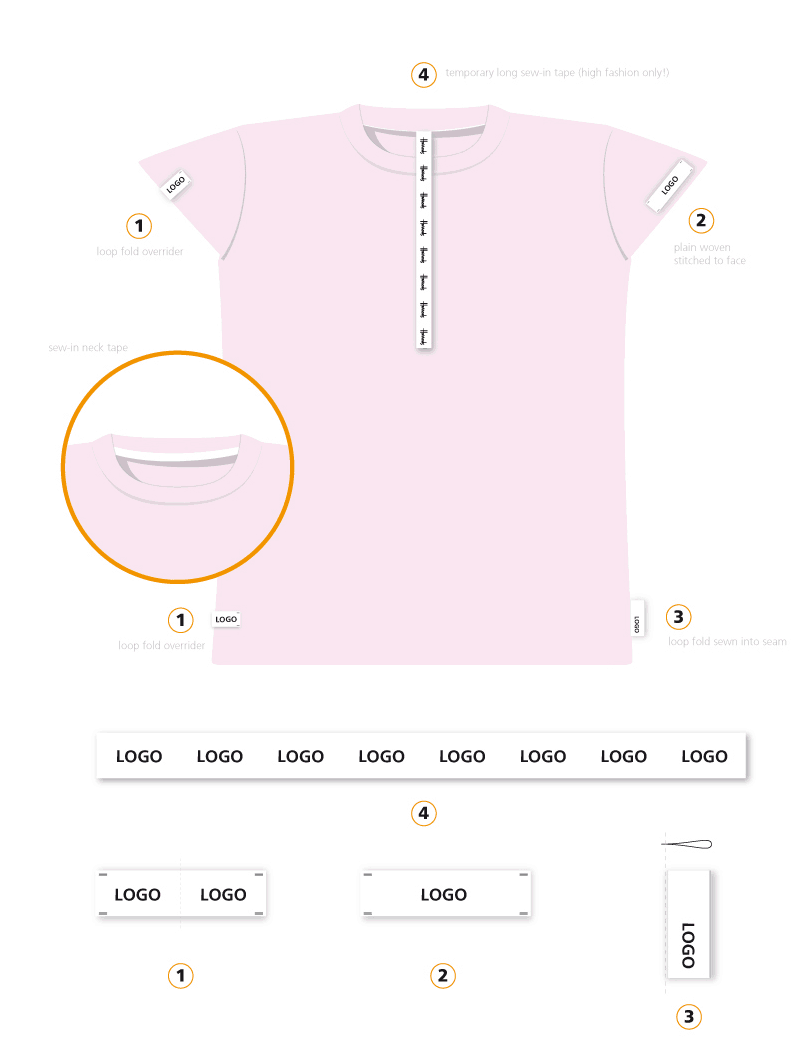

Regular woven labels are positioned in the neck seam or general neck opening area as it is the most prominent place when the product is displayed on a hanger or when folded and laid flat.

More contemporary brands or those wishing to stand out by being different often choose to feature additional branded devices on their garments and often it is the actual physical position of the woven label that actually becomes the product branding identity. (In the same way that a woven crocodile reflects one particular fashion brand and a large screen-printed ‘swoosh/tick’ IS a huge sports brand.) A simple white t-shirt can become more premium through its use of labelling and detail.

Replacing one button on shirt with a different coloured one or using a highlight coloured thread on one button hole becomes synonymous with the brand and it is these attention to details that makes people desire them. Sometimes it is the fashion designer introducing these details, other times it is the packaging graphic or product branding designer that suggests these. Noticing such details reflects on the person wearing them and others that notice them.

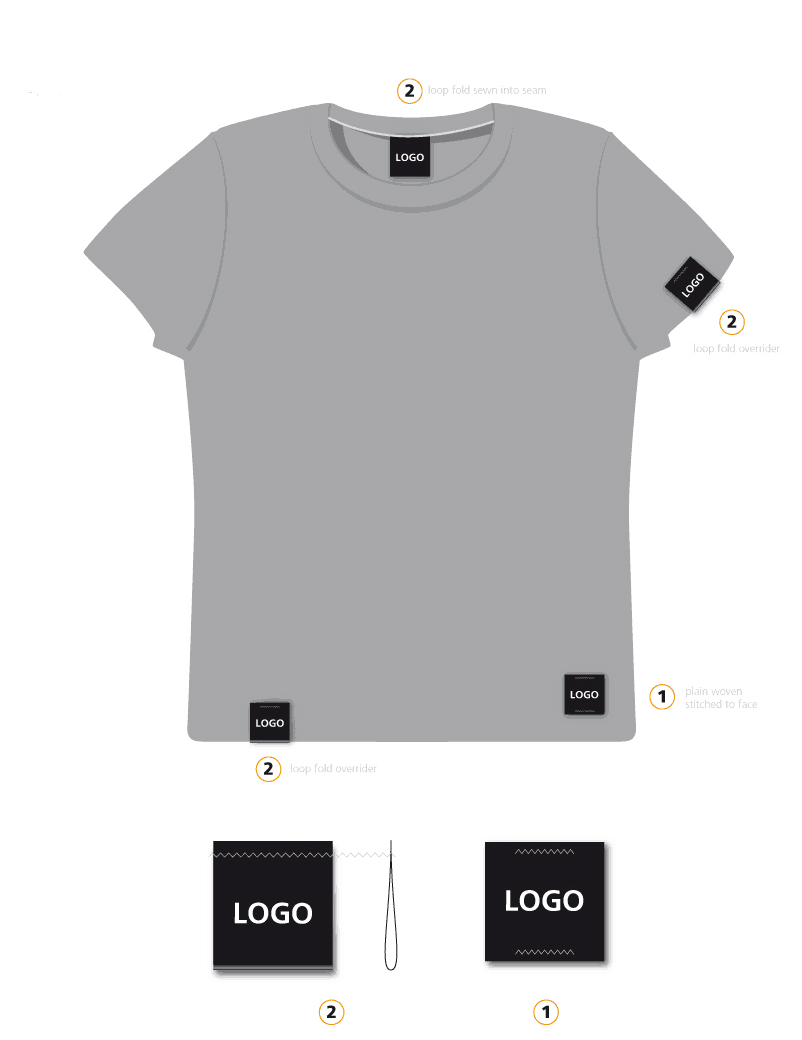

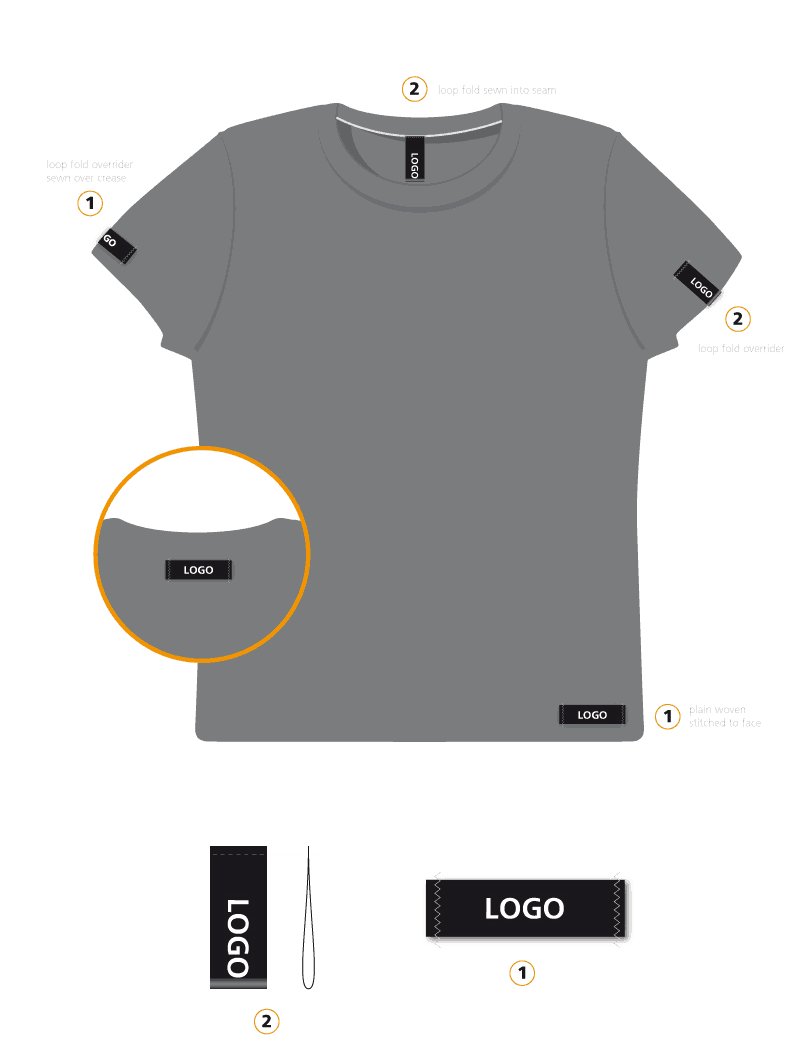

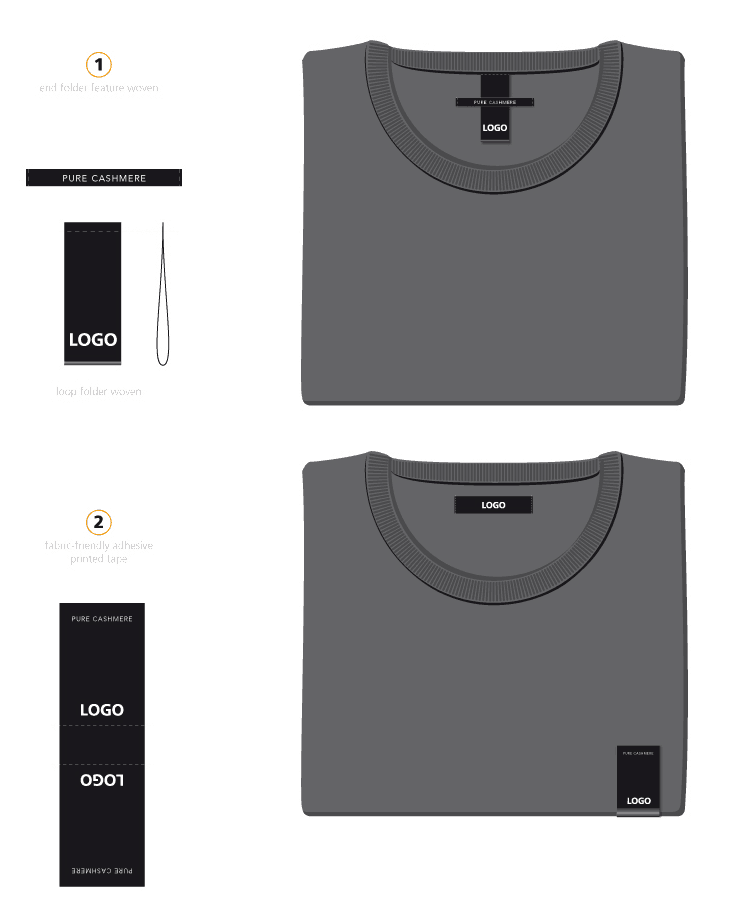

So, we’ve put together a series of templates that show a few of the possible logo and woven label product branding positions that can help add a difference to garments.

SQUARE FORMAT LOOP FOLD WOVENS

This kind of label can be sewn into neck seams and used as an over-rider on sleeves and on the base hems of t-shirts.

RECTANGULAR FORMAT LOOP FOLD WOVENS

Narrower versions of the woven loop label allow the logo to be used vertically as a point of difference. They can be used as a ‘cuff’ on sleeves or sewn across the arm.

LOOP FOLD WOVENS

Here a narrow loop fold woven label retained by ‘premium material feature’ woven. Below, a temporary double-sided printed material label can be tacked in position for merchandising purposes (a more premium alternative to self-adhesive labels!)

HORIZONTAL END FOLD WOVENS

Two narrow end fold woven labels sewn in horizontally in close proximity either to the neck or tacked temporarily to the body of the garment.

Additional repeating woven tape is a useful product branding tool for merchandising in-store, wrapping either around a permanent woven or around body of garment.

LOOP FOLD WOVENS

Long woven tape sewn into the neck for temporary in-store product branding, but with side sewn loop fold woven label on seam edge.

Many of the suggestions above have been shown as woven labels, but they could equally be screen-printed or embroidered in position where budget or manufacturing capabilities allow.

We hope to follow up this post with information on using similar techniques for formal shirts and jackets.